Designs and Designing: Common Questions

Just Ask Jeff : There seems to be a lot of questions out there about gemstone designs and designing. Here are some common questions and answers to them.

11 Minute Read

There seems to be a lot of questions out there about gemstone designs and designing. Here are some common questions and answers to them.

Do I need to learn Gemcad?

If you want to design gemstones then the answer is yes, you need to learn Gemcad or some other type of CAD program that was written to create gemstone designs. If you just want to cut stones then the answer is NO, there are all types of quality designs already created and published by me and many other people. All you need to do is start cutting these already created designs. There are a lot of designs out there available and you will never run out of interesting designs to cut.

Is learning Gemcad hard?

It depends on your computer back ground, especially if you are using the older DOS version of the program. But even the new Windows version does have a significant learning curve, at least before you can really create any truly interesting and original designs that will work. It is important to note that just because a person has learned the basics of Gemcad (or any program) does not mean that they will know anything about creating a quality gemstone design.

Learning the program does not mean that a person can create a quality design, or even a design that will work. There is a large component of experience and talent that is needed to really create a unique faceting design that will perform well. There is also a certain amount of well art is about the best explanation I can think of that is required. Some people have all of these components, some people do not. The designs will generally speak for themselves.

What about other indexes besides 96?

Some people have made the comment that other indexes are better for creating unique designs. This is quite frankly not true in most cases, but does some what depend on your goals.

The 96 index gives the widest range and versatility of all indexes (below it) and exactly the same range in a lot of cases as other indexes (for example a 32 or 48 index).The 72 index is identical to the 96 index with the exception of the 9 symmetry, which I will talk about later in this article.

Note1: The 120 index is quite versatile and solves some problems and I do occasionally use it. But I find 120 teeth more difficult to use on a practical basis when cutting just because there are so many teeth.

The simple fact is the 96 index is the most versatile and one of the best index choices. The sheer number and quality of designs that are created on a 96 index should be obvious proof of this fact, to most anybody who is paying attention.

The main design types/symmetries that a 96 index will not accommodate are of course odd indexes (odd numbers 5, 7, 9, 11) like 77 and 80 indexes are used for. There are a few other odd indexes depending on your machine. But over all, with the exception of odd numbers the 96 index has the best range and the most versatility. That is why almost all faceting machine manufacturers ship their machines standard with a 96 index from the factory. If a designer cannot design something unique on a 96 index, it is the designer's fault not the index.

It has been stated that the 96 index is a poor choice because the tooth to tooth angle is 3.75 degrees and that a 72 index is better because it has a tooth to tooth of 5 degrees. While the math of this statement is correct, very little else is.

This statement has so much wrong with it that it is hard to pick a place to begin. This statement is basically misleading and just takes into account one factor out of many, many factors in designing. It is very far from the whole story and while the math is right the application is wrong. In other words real designs do not work that way.

For one thing designs seldom use two teeth on an index gear next to each other. What I mean is that on a 96 index gear (or any gear that has a reasonable amount of teeth) you almost never use index number 96 and 1 next to each other and never at the same angle. In other words there is almost never just one tooth between facets at the same angle.

At the very closest, and at an extreme example a design would use index 95 and 1 for breaks with a 96 main in between them. The main 96 is at another angle and not part of the same tier. That makes a tooth difference of 2 teeth between 1 and 95 indexes and an angle difference of 7.50 degrees (2 x 3.75) between the breaks.

So it is pretty obvious to see the fallacy of the earlier statement about there only being 2.75 degrees difference between facets if you use a 96 index gear. You can make the argument that there is only 3.75 degrees between all three facets (95-96-1), but that does not take into account the angle difference between tiers of the mains and breaks, which is usually at least a few degrees different and of course not optically even in the same plane. These tiers are in another plane from each other and cannot be lumped together.

Remember 95-96-1 is a very extreme example, seldom does a design use 95-1 breaks and 96 as the main. The reason for this is simple, having facets this close together makes them very difficult to cut unless the stone is very large. Also optically having facets this close together is not ideal and is seldom done, no matter what index is used, 72, 80, 96, 129, ect.. Go look at some published designs, I seriously doubt you will find a design with 95-96-1.

Typically designs use many more teeth in between facets and here is an example that everybody can relate to. Yes, on a 96 index. I doubt whether anybody can dispute that the standard round brilliant is one of the best designs of all time.

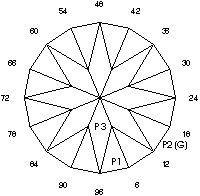

Typical round brilliant, which almost everybody that facets has cut at one time or another.

P1 43.00 03-09-15-21-27-33-39-45 51-57-63-69-75-81-87-93

P2(G) 90.00 03-09-15-21-27-33-39-45 51-57-63-69-75-81-87-93

P3 41.00 96-12-24-36-48-60-72-84

OK, now note that the pavilion breaks are at 3-93 and the main is at 96, which is a different angle/tier than the 3-93. The 3 and 93 indexes are 6 teeth apart from each other. The main which is at a completely different angle is in the middle, 3 teeth from either of the breaks. As you can see that nothing is 2.75 degrees apart and the teeth are all a minimum of 3 apart (8.25 degrees).

You will find that almost all designs whether done on a 96 index or some other index are never created so that facets are 3.75 degrees or closer (tooth to tooth). In most cases the angles between teeth will be much larger and vary dramatically. Of course some of these variables depend on the individual designer, but then that is the subject "designing".

Another problem with this statement of 2.75 degrees/tooth is that facets and tiers are layered like a wedding cake. This means that the facets/tiers are 3 dimensional and there are all types of compound angles and combinations happening between the facets and tiers. Just making the statement that a 72 index is best and everyone else is wrong to use a 96 index is ludicrous and hubris. There are a lot of things that contribute to a quality design and many, many more than just the index.

One last thing. Great designs can be created on any index, whether a design is great or not depends on the designer. It is a poor mechanic that blames his tools.

Universal angles and design ranges? Well this is a deep subject and more involved than I am going to cover here. There is no real universal set of angles that will work with everything. That being said there are some designs that will work in a wide range of refractive indexes with no changes. If you look at my designs you will notice that I have made a lot of effort to check my designs for a wide range of refractive indexes.

My designs will often say… "Cut in refractive indexes 1.54 (Quartz) to 1.93 (Zircon) with no changes…" When I say this I mean that this design can be cut in any refractive index in the range I have listed with absolutely no angle changes. I have tweaked and tested this design to perform well in that range of indexes. I will always list a ray trace and a Light Return percentage. The Light Return number % listed is lowest refractive index listed in the range given (Qtz in the above example).

The fact of the matter is that when I create a design I am trying for a particular look, performance, and style. Generally you may have noticed I make my designs for optimal performance in the lower refractive ranges 1.54 (Quartz) and 1.62 (Tourmaline/Topaz). Most of my designs will ray trace out at 80% or better in these low refractive indexes. There are some exceptions, but generally mid to high 80's.

In most cases because my designs perform well in low refractive indexes, cutting that very same design in a higher refractive index usually results in a few percentage of net gain in the ray trace. For example, if the ray trace for a Tourmaline design is 86% and you cut it in Sapphire, the ray trace will generally improve 2-4% and be around 89% or 90%.

Note2: It is important to realize that I will often opt for a deeper design to improve color, or create an effect of some kind in the design I want. So ray traces are not always a good indication of the over all design performance.

Do I need to be able to tangent ratio designs?

On my designs the answer is no. There are several reasons for this but to put it simply.

In almost all cases you can take a design that is made for a low refractive index and go up (higher RI) with no changes and generally get a slight to fair improvement in light ray trace. Most of the designs, mine anyway, are already in the 80% light return area or better. So there is not a lot of improvement to get and my designs can be cut in higher refractive index ranges I have listed.

But you almost never can take a high refractive index design and go down in refractive index. There are exceptions but in most cases if the design in question is made for a high refractive index it will loose significant performance and light return if you try to cut it in a low refractive index.

Note3: I am not talking small refractive index changes like from 1.76 (Sapphire) to 1.73 (Garnet). This type of change is so small that there is no real difference. I am talking about refractive index changes of .05 or more. Like from 1.76 (Sapphire) to 1.62 (Topaz) or 1.56 (Beryl).

No tangent ratioing will not help. Using tangent ratioing keeps the tiers and design the same proportionately to the original. But the real problem is that a design made for 1.76 (Sapphire) is generally not adaptable to 1.62 (Topaz) because of the angle difference in between tiers.

In layman's terms the design sweet spots between refractive index 1.62 and 1.76 are different enough that a design made for 1.76 will often not work.

Then why will a 1.62 design generally improve in 1.76? Simple. The sweet spot for the lower refractive indexes is much smaller and makes a tighter design, so it will work better as the refractive index get higher. The 1.76 design is often looser and uses a wider range of angles that the lower refractive index will not perform in.

Note4: This is a very simplified explanation of what is happening and there are both exceptions to this and other things happening in the designs as well that may impact the performance.

Are Odd Indexes better or brighter?

In general, the answer is no. There maybe a very slight difference one way or the other in performance between an odd and even design. But nothing significant. The one thing that I did find in my experimentation (years ago) is that the odd number designs sometimes caught the eye differently. But to do so the odd designs had to be noticeable as being odd.

What I found was that basically once the number of facets on the girdle/design went over a certain amount there was no real difference to the eye. At some point a round is a round, no matter what. It all looks the same to the eye, it does not matter if it was odd or even. In other words a 9 symmetry and 8 symmetry round brilliant look almost identical to each other and there was no real preference among people I showed the cut stones to and asked them to pick which one was better. A lot of people that were not faceters did not even notice any difference between the stones.

Another thing about using odd symmetry is that quite frankly there is not a lot you can do with most of the odd indexes that is practical. Yes you can get a few interesting and/or weird cuts. But that is about it.

Performance in a lot of the more simple odd symmetry designs is poor, often because the facets are odd and do not line up to reflect off of each other. Another thing is that because the symmetry is odd there is no easily devisable index numbers to split tiers off of. Just try to make an oval with 9 sides that has mains.

My conclusion was/is that odd symmetry designs can some times make an interesting cut or a novelty but there is not a lot of practical application for them.

Note5: I did come up with a couple odd symmetry designs that I have been meaning to publish sooner or later.

Related Articles:

Jeff R. Graham

The late Jeff Graham was a prolific faceter, creator of many original faceting designs, and the author of several highly-regarded instructional faceting books such as Gram Faceting Designs.

Related Articles

How to Use a Color Wheel for Gem Faceting

Cutting Natural Rough Stones: The Breaks

How to Cut a Simple Portuguese Gem Design

Common Books About Stones and Faceting

Latest Articles

Identifying Synthetic Gems

Ten Big, Beautiful, and Affordable Engagement Ring Stones

Rhodochrosite Value, Price, and Jewelry Information

Ruby and Sapphire Survey: Where Do You Draw the Line?

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!