Diamond Specialist Certification Course

Introduction to Diamond Faceting Equipment

Purchase Diamond Specialist Certification Course

Learn the fundamentals of diamonds — from optical and physical properties to grading and ethical and legal issues. Learn to distinguish natural diamonds from synthetics and diamond simulants. Keep the kit, which includes one natural, jewelry-grade diamond. If you successfully pass the quiz and gem identification test, then you will be an IGS-certified Diamond Specialist.Answer: For non-professional gem cutters, finding quality diamond rough and the right diamond cutting equipment can be challenging. However, it can be done.

No Secrets to Diamond Cutting

In the world of diamond cutting, the main thing you need to keep in mind is "Time is Money." Everything is designed for cutting diamond rough and finishing the stone in a timely manner. That's not to say that you can't cut a diamond on a few of the machines that are out on the market or that you need to design or make a special machine just for diamonds.

The Machine You'll Need

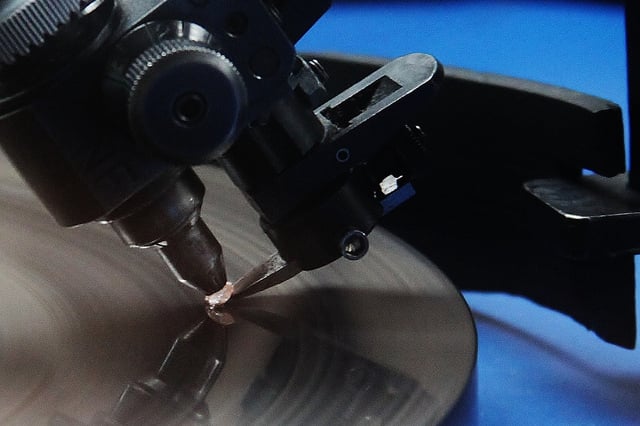

However, what you will need is a machine that is really beefed up motor-wise, at least a ¼ horse power motor and a pulley system to give you at least 1,500 to 2,500 rpm. (Many may say you don't need all that speed. Speaking from experience, if you want to finish the diamond before you are 110-years old, it helps). You'll need the machine to be heavy and anchored down due to the vibration factor. (I've repaired diamonds on a Graves Mark 1 machine by replacing the pulley to gain more rpm. But when I turned on the machine it damn near walked out of the room).

You'll also have to invest heavily in cast iron laps. Get at least five, one for each grit. You'll have to charge them yourself and keep them in a very clean environment.

Diamond Rough

As for diamond rough, you'll find many pieces have a rind on them that makes them very hard to grade until you get it off and see into them. Be sure to brush up on the crystallography of diamond. You'll need it.

If you keep the heat down when you are cutting, a standard quill and dop system will work. You'll have to use oil for cooling. Water based coolants won't work.

If you don't plan to work with diamond rough on a regular basis, my advice is don't worry too much. You can find information on cutting diamonds in Faceting For Amateurs by Glenn and Martha Vargas. There is no secret to diamond cutting. You follow the angles based on the refractive index just like any other gemstone. It's just dirtier, noisier, takes more time, and is very expensive lap wise. That's all.

Ron Campbell, Central Coast Gem Lab

Jeff Graham on Getting Diamond Rough and Cutting Equipment

I'm going to pass on some (edited) comments from award-winning gem cutter Jeff Graham that I think you might find helpful.

The main difference between cutting diamonds and cutting colored stones is getting good rough. I know for a fact it's not really available. If you see diamond rough for sale, I'll bet it's not as advertised. The machines you'll need are similar, but you'll need one that runs quite a bit faster, cast iron laps, and a diamond claw to hold the diamond rough pieces. (They get red hot during cutting). The claws are adjustable for the facet settings, but you may need to buy or build more than one, depending on the type of stones and shapes you want to cut.

Mr. Graham also recommended a book by Sofus Michelsen and Basil Watermeyer, The Art of Diamond Cutting. The following quote from the introduction I think makes it clear why it's perfect for a small-timer who knows something about colored gemstones and wants to give diamond cutting a try.

Amateur and semi-professional colored stone faceters have a natural inherent ability that enables them to explore new frontiers while continually striving to perfect their craft. They constantly experiment with different materials, angles, and polishing techniques in order to improve upon what they achieved on the last stone they cut. Most are self-taught and learned their skills through trial and error, magazines, books, etc. … The whole idea behind this book is to encourage the colored stone faceter to use his/her skills in a rewarding and profitable venture …. Experienced colored stone faceters know that it only takes a little courage and the knowledge that repetition is the mother of perfection.

Hope this helps,

E. Jakeman, Ogden, Utah

Using a Facetron for Cutting Diamond Rough

One more note about diamond cutting equipment. 1,500 rpm is just about minimal for cutting. However, the Facetron machine, which only runs at 1,400 rpm, will cut diamonds very slowly. (Facetron also makes a diamond claw. It's about a ¼" dop size and can easily be modified). As for machines with higher speeds (2,500+ rpm), I don't think those speeds would ever be used on any other gem material aside from diamond. But sooner or later, a few gem cutters are going to see some diamond rough and wonder what they could do with it. I hope this information saves them from banging their heads against the wall in frustration. Finding good diamond rough, well, that's another problem.

E. Jakeman, Ogden, Utah

Why Good Diamond Rough is Hard for Non-Professionals to Find

Some years ago, Norman Jarvi cut a diamond at the Tucson show using a Facetron. He made his point, but it never gained much popularity for that use.

The main drawback for the occasional diamond cutter is finding good diamond rough. Professional diamond cutters, who usually purchase the lots, are reluctant to sell off their better pieces. Even when good material is available, a lot of cutters are surprised at how close the wholesale price is to the finished stone price. There is not nearly the room for profit in diamonds you find in colored stones.

I have to add one more piece of advice for anyone new to cutting diamonds. Each facet needs to be cut in the particular direction of least hardness. If you go the wrong direction, the stone will not cut. Experienced cutters can read the grain and set the stone properly. For the beginner, you can tell by the sound. On the direction of maximum hardness, there is a terrible screech and lots of sparks. It doesn't take much experience to tell when you have it wrong!

Sincerely,

Donald Clark, CSM IMG

(Editor's note: for more opinions and information, see our article on Diamond Cutting for Hobbyists: Getting Started).

International Gem Society

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!