Precision Faceting A Story Gemstone: Faceting Equipment

Today's custom gem cutters use faceting equipment for precision work and design inspiration. Take a look at the toolkit of the new lapidary renaissance.

3 Minute Read

Moon and Sunshine: A Quartz Story

Moon and Sunshine heard about my work and phoned me. This local couple planned to have a small, private ceremony on the summer solstice to celebrate their union. They wanted two precision faceted gemstones for the occasion. Both Moon and Sunshine had alternative ideas about the ceremony and the exchange of rings. We met at a local coffee house to discuss their story.

Moon was interested in a traditional white gold and diamond ring. However, her ethics wouldn't let her support the gold or diamond industries. She showed me a rough natural quartz crystal point that Sunshine had given her early in their relationship. She asked if I could instead create a gemstone design using the crystal. Exceptionally clear and the right size for her silver ring, it would work perfectly.

Sunshine didn't want to wear a ring. As an organic farmer, he would risk losing or damaging it. Instead, he wanted a single golden-yellow stone from Moon as a symbol of their relationship at the ceremony. Also, he wanted me to create a design for the stone. After looking a several options, he chose one of my most sought after collector stone designs.

The couple asked me to make their stones unique. I assured them I could add embellishments that would add beauty and individuality. We met two more times to verify the selection of Sunshine's rough stone and sign off on the designs. I was honored when Moon and Sunshine invited me to the ceremony. They made me a part of their story.

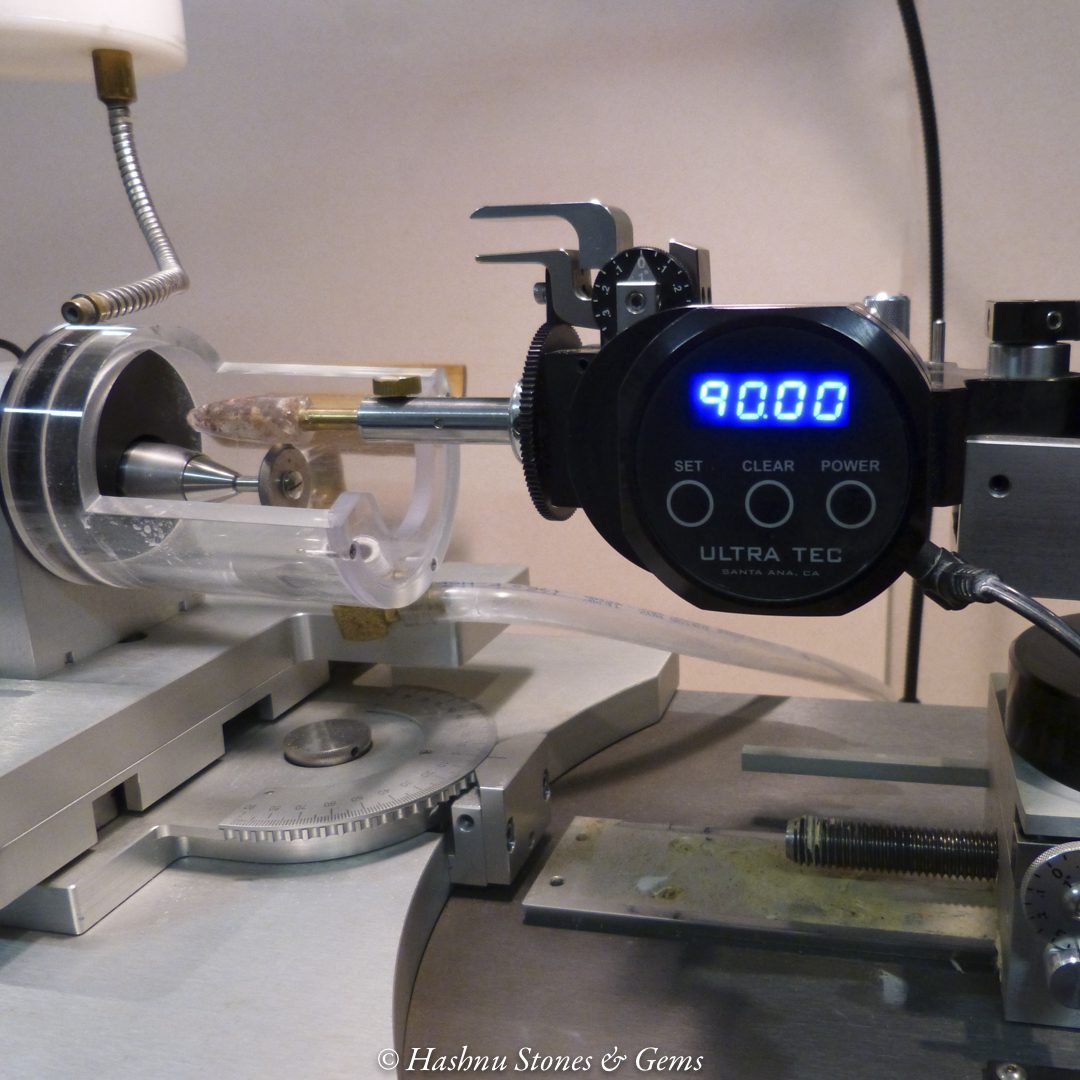

Modern Faceting Equipment for Precision Cutting

Custom faceters use a very different level of faceting equipment than what's used in factory cutting. Price and precision are the main differences. Factory cutting is geared to bulk production at a profit level that will sustain the company and its owners. Controlling costs and output comes first. Quality comes second. Customer faceters put quality first. Precision modern faceting equipment and the best tools available, combined with extensive knowledge of gemstone properties and cutting techniques, make that possible.

Modern Faceting Machines

Over the past 200 years, the faceting machine has progressively developed into an exacting, precision tool. Today, state-of-the-art faceting machines can cut within one one-thousandth of a centimeter. I recommend reading Glenn Klein's book, Evolution of Faceting Machines. It offers a delightful and complete overview of the history of this principal faceting equipment piece.

Tools For Fantasy Cutting

Currently, Hashnu Stones & Gems and other custom lapidaries regularly develop and test new faceting tools. When combined with faceting machines, they make it possible to cut concave facets. This new faceting equipment is ideal for fantasy cutting. Faceters can sculpt gemstones in ways unimagined decades ago. Fantasy gemstones are moving the craft from design to sculptural art.

Laps and Polishes

Over the last decade, discoveries of new materials, compounds, and rare earth minerals have lead to the manufacture of new laps and finer abrasives. These make possible finer details and extraordinary polishes for gemstones.

A Lapidary Renaissance

These new developments in faceting equipment inspire custom faceters. More precise faceting machines, new carving and fantasy tools, and sophisticated cutting and polishing compounds help us develop new techniques. In turn, we can create new and wonderful artistic faceted gemstones.

Based on this, I'd say we're in the middle of a lapidary renaissance. One day, these tools and techniques will become affordable and standardized for factory cutting. Until then, the custom faceter is both the architect and gateway to the cutting edge of modern gem design.

Precision Faceting a Story Gemstone: 5-Part Series

Faceting Equipment (Part 3)

Custom Faceting Advice (Part 5)

Mark Oros

At Hashnu Stones & Gems, we work and play with some of nature's finest creations, gem stones, opals, agates, jaspers, and fossils. We custom facet and carve a great variety of materials for our patrons, collectors, jewelers, artists and our friends. We also provide fellow lapidarists with facet-grade quality rough material for their own creations.

Related Articles

Quartz Value, Price, and Jewelry Information

How Does Quartz Form?

What is Gemstone Luminescence?

Top Spots for Gem Hunting in the US

Latest Articles

Celebrity Engagement Rings

Ruby and Sapphire Grading Tools

Cerussite Value, Price, and Jewelry Information

Ouro Verde Quartz: History and Treatment

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!