Getting the Best Gem Yield from a Crystal

Cutting crystals for the best gem yield is a critical skill for faceters. This walkthrough can help novices learn how to visualize the gems before cutting.

4 Minute Read

(Previously, I discussed this crystal in an article on calculating how much money you can make from cutting rough).

So, let's say I've bought this aquamarine rough. How do I cut it for the best gem yield?

Take Your Time

Examine the crystal very closely and take your time. Don't make any fast decisions. If you're not sure, just give it as long as it takes. Sometimes, I think about a piece of rough for a long time. Once, I mulled over a piece of spinel for a year before I cut it. I finally found the design it needed.

This quality piece of aquamarine will yield very high in about any shape(s) you want. However, you still face a lot of choices. While some depend on the best mass yields, others depend more on what you want to get out of the crystal, particularly what shapes.

Consider the Gem Shapes

I say shapes because I often opt for a lower yield to get a shape or design I want or that I know will work especially well for the rough. Some shapes just sell better than others, too. Always consider this factor. I usually try for shapes such as trillions, square cushions, and cushions. I also try for matched sets of about any type.

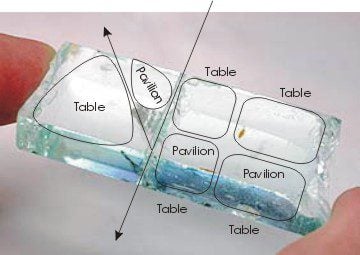

In the photo to the right, I've marked a basic set of outlines I would cut from this aquamarine. Keep reading. You might find some of my approaches to this crystal surprising.

Choosing the Direction of Your Cuts

For this rough, the first cut is obvious. Cut the crystal along the growth line. You'll get two pieces: one a little over a ⅓ of the length of the rough (left), the other a little under ⅔ of the length (right).

The main stone outlined on the left side section is a trillion. (For this gem, I'd use my Signature #4 design, one of my favorites for aquamarine).

Take a look at this closeup photo of the left side section. Notice the flaw in the middle of the crystal, where the arrowed line starts. (The larger right section is clean, without flaws). Now, notice what looks like a flaw beneath the arrowed line? That's only a reflection of the actual flaw, which is oriented and running at about 45° towards the crystal's edge. The point of the pear outline also happens to point to the crystal edge that way.

If you look at the next photo, you'll see that cutting at a 45° angle with a saw blade will just about preform the pear pavilion (on one side) and, of course, help point up the trillion bottom. Note: I rotated the trillion a bit to get a long side along the saw cut. Due to the 45° cut, you'll get a pear quite a bit bigger than if you'd just cut at 90°.

Sawing at 45° basically solves two problems at once. It creates pavilion points for the trillion and pear and removes a flaw.

Trimming Scraps Can Also Yield Gems

I'd use an ultra thin saw blade and trim the trillion on all three sides of the pavilion (and the pear on the second side). The trimming won't leave large scraps. However, they could yield several carats of cut stones. Depending on the gem design you use, the scraps from the trillion pavilion could cut a couple of carats each.

Cutting for the Tables and Pavilions

The pear's table is actually on the bottom of the crystal, as it appears in the photos. The trillion's table is on the opposite, top side.

Now, the next cut may surprise you. Go back and look at the photo with the shape outlines. Note that on the larger right section of the aquamarine, I've marked two square cushions and two rectangles. What you may not have guessed is how I'd trim the crystal and exactly where the stones' pavilions will be.

In this photo of the end of the crystal, I've marked where I'd cut. With a trim saw, I'd cut at about 45° through the middle of the length of the right section of the crystal. The tables of these stones will be at 4 o'clock and 10 o'clock, respectively. (The top of your computer screen marks 12 o'clock). This cut will yield much larger stones. However, inexperienced faceters may not even think of taking this approach.

For the two rectangles, I'd consider my Aqua Cisir cut. For the square cushions, I'd probably use my Nigerian Cushion. The Aqua Cisir design has a keel and would really yield well in this material. The cushion is just a classic cut.

Cutting for the Best Gem Yield: Conclusion

I think cutting the way I've outlined would give you the best gem yield for this crystal. The gem designs I've recommended will help yields and also improve colors.

Remember, take your time. Think about the rough before doing any cutting.

Jeff R. Graham

The late Jeff Graham was a prolific faceter, creator of many original faceting designs, and the author of several highly-regarded instructional faceting books such as Gram Faceting Designs.

Related Articles

Buying Gemstones in Afghanistan: A Beginner’s Guide

The White Paper Test and Rough Gem Buying

Tips for Cutting and Polishing Halite

Barion Cut Designs for Colored Gemstones

Latest Articles

Amethyst Sources Around the World: The Geological Story Behind These Purple Gemstones

Brazilianite Value, Price, and Jewelry Information

Ruby-Glass Composites vs Leaded Glass Clarity Enhancements

Morganite Buying Guide

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!