Lab-Grown Diamond Production Methods

Lab-grown diamond production methods simulate the natural conditions that produce diamonds deep underground. Learn how the HPTP and CVD processes work.

4 Minute Read

Lab-grown diamond production methods try to recreate the high pressure and temperature conditions that form natural diamonds underground. Let's examine that natural geological process first.

How do Natural Diamonds Form?

Natural diamonds form deep underground, about 177 to 241 km below the surface. Pressures at this depth can reach nearly 50,000 atm. (One atmosphere, or "atm," is equivalent to the air pressure at sea-level). Temperatures can range from 900º to 1,300º C. These intense conditions compress carbon into its most compact form, creating diamonds in magma. Ancient volcanic explosions brought these diamonds to the surface, through the formation of rocks known as kimberlite.

Interested in this topic?

This article is also a part of our Lab Grown Diamonds Fundamentals Mini Course, in the unit Introduction to Lab-Grown Diamonds.

What are the Main Lab-Grown Diamond Production Methods?

There are two main lab-grown diamond production methods: the high pressure/high temperature process (HPHT) and chemical vapor deposition (CVD). Both methods are commonly used, but CVD is becoming more popular for producing gem-quality synthetic diamonds for jewelry. HPHT is used more often to create synthetic diamonds for industrial use.

Can You Distinguish a Natural Diamond from a Lab-Grown Diamond?

Both HPHT and CVD produce diamonds with the same optical, physical, and chemical properties as natural diamonds. However, these laboratory processes do leave some telltale signs that gemologists can identify by close inspection.

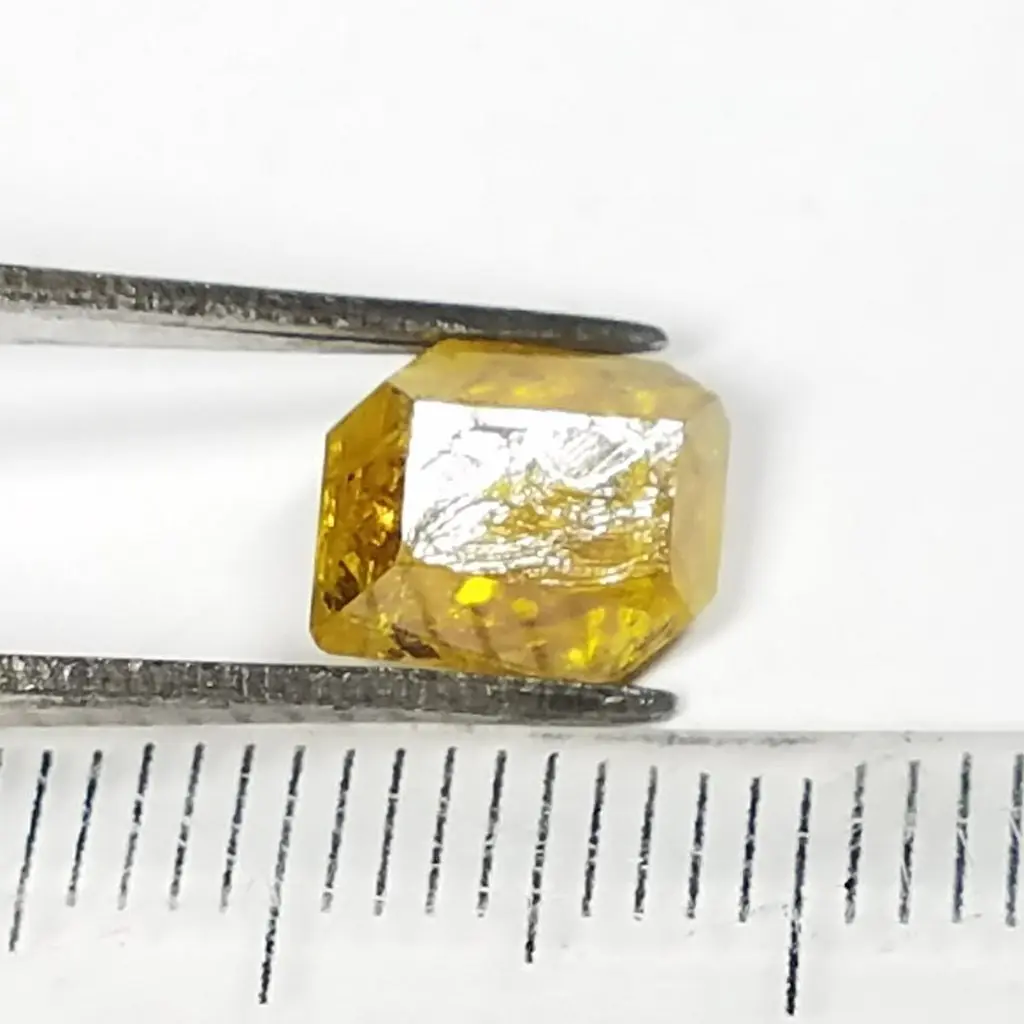

In rough crystal form, the differences are more readily discernible. Natural diamonds form with eight sides of growth, forming an octahedral crystal shape. On the other hand, HPHT diamonds form in a cuboctahedron shape with 14 directions of growth. CVD diamonds form in a cubic shape with one direction of growth. Of course, all diamond crystals form in the isometric system, and all these shapes fall within this system.

The HPHT Process

Developed in the 1950s, HPHT was the first method developed for diamond synthesis.

The process begins by placing into a press a capsule containing a carbon starting material, a mixture of metals called a metal flux, and a small diamond seed. The carbon starting material used in this process is usually graphite, a common mineral composed of pure carbon.

The capsule is then heated to temperatures of 1,300º to 1,600º C and pressed to pressures up to 59,200 atm. This dissolves the carbon source into the metal flux. The makeup of the metal flux varies, but often includes a mixture of iron, nickel, and cobalt, which helps reduce the temperature needed for diamond formation. The dissolved carbon source can then pass through the molten metal mixture to crystallize around the diamond seed, forming a lab-grown diamond.

The HPHT process can take from hours to weeks, depending on the desired size and quality of the stones.

Presses

There are three types of presses commonly used in HPHT diamond synthesis: belt, cubic, and split-sphere (also known as BARS).

The belt press was the first press used in lab-grown diamond production. With various advancements and alterations, it remains in use today. The belt press uses two anvils to apply pressure to the capsule from above and below.

The belt press led to the development of the cubic press. A cubic press functions like a belt press but uses six anvils, in order to work with larger, cubic materials. Although a cubic press can apply greater pressure than a belt press, technicians can't scale it the same way as a belt press. As a result, cubic presses aren't used as often as belt presses.

The split-sphere press uses eight outer anvils and six smaller inner anvils, in order to maximize pressure on the capsule. The cylindrical capsule is then placed into an oil-filled barrel to accelerate heat transfer. This helps achieve higher temperatures at a much faster rate.

Treatments

Most HPHT diamonds will undergo further heat treatments after they come out of the presses. These treatments will improve their color and clarity and can even create fancy colored diamonds. For example, heat treatments with boron can turn HPHT diamonds blue. Heat treatments with nickel can turn HPHT diamonds green.

Radiation treatments can also create pink and red colors in HPHT diamonds.

The CVD Process

The CVD process begins by filling a chamber with a mixture of gasses, including carbon, hydrogen, and oxygen. Next, a substrate is added to the chamber, usually a thin sliver of diamond seed, although graphite can also be used. The chamber is then heated to temperatures of 800º to 900º C, using microwaves, lasers, or a hot filament. The energy from the heat source causes the carbon to precipitate out of the gaseous mixture and stick to the substrate, which begins to crystalize into a diamond.

Technicians must stop the CVD process frequently, so they can remove any graphite that crystalizes around the diamond.

CVD can take from days and weeks, depending on the desired size and quality of the stones. However, dozens of stones can be grown at the same time.

Treatments

Most CVD diamonds come out of the chamber with brown or yellow colors. In order to be sold as white or colorless diamonds, these stones must undergo heat treatment. After formation, CVD diamonds can also receive treatments to create fancy pink or red color.

Adding boron or nitrogen into the chamber during formation can also create fancy colored blue or yellow colors in CVD diamonds.

Lab-grown fancy colored diamonds, whether produced via HPHT or CVD, are much more affordable than their natural counterparts.

at VRAI

Amanda Butcher

Amanda is a student of geological sciences and environmental studies at Tufts University. She grew up hiking and mountain biking in the Bay Area and continues to explore nature and learn about the beautiful gems and minerals it forms in her free time.

Related Articles

Diamond Value, Price, and Jewelry Information

Is an SI Clarity Diamond a Good Deal?

Vintage Engagement Rings: Guide to Four Eras

How to Grade Fancy Cut Diamonds

Latest Articles

Morganite Buying Guide

How Do Amethysts Form?

Rhodizite Value, Price, and Jewelry Information

Pearl Treatments and Enhancements

Never Stop Learning

When you join the IGS community, you get trusted diamond & gemstone information when you need it.

Get Gemology Insights

Get started with the International Gem Society’s free guide to gemstone identification. Join our weekly newsletter & get a free copy of the Gem ID Checklist!